GoClaws & SnoClaws

Note- Only difference is the fasteners.

Every aspect of the Flex-Trax Technology has been carefully considered and implemented to Maximize Traction Capability.

Tires inherently BULGE at the baseline of contact zone. Flex-Trax Self-tensioning, Positive Locking traction device actually gets tighter with loads applied.

The Tire Depicted in the Video Below

Did at one time Have Sufficient Air Pressure,

until Exposed to Cold Temperatures!

See-Consequences of Air Pressure Changes

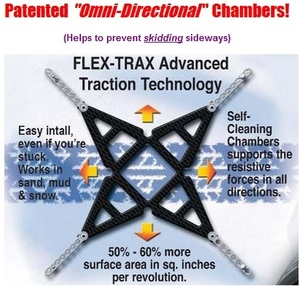

Flex-Trax Has 50-60% more surface area contact than tire chains and cables! Each of the self-cleaning voids (Chambers) have sharp angles that grip the surface in all directions which help prevent skidding sideways. Said angles form a "V" in all directions. Widely known in the conveyor / material handling industry as Chevrons. These chevrons envelop the contact surface and leading edge of the Flex-Trax which assist in the self-tracking and self-centering of the mounted unit. As load is applied these leading angles resist deflection and automatically pull to the center of the tire as the trax tend to get tighter, which also provides for the self-tensioning capability.

What are the *Problems with Cheap Tire Chains?

Study of Tire Dynamics

Engineering Research -

Troubleshooting the premature failure of Tire Chains..

Technology Leadership Award!

Registered Copyrights / Trademarks

FLEX-TRAX™ GoClaws™ SnoClaws™ and WeatherClaws™

FLEX-TRAX™ work utilizing a distinctive patented advanced style and design. Utility Patent for Method & Apparatus. This unique traction system is composed of tread faced traction segments, that can be rapidly and effortlessly secured to your vehicle's drive tires. This product fuses proven techniques of mechanical engineering, physics, material handling, and hydraulics to achieve a modular style and design that offers superior overall performance compared to mud / snow tires, tire chains, Auto Sock, and other competing Alternative Traction Devices.

FLEX-TRAX™ Tread Pattern is a unique non clogging design and the only such device on the market today. Original tire tread patterns for adverse conditions have involved beefy lug member’s protuberances (knobbies) extending outwardly to bite into the snow. Whilst in operation, the grooves which form these extensions become filled with fluid solids to the height of the extensions, making the impact profile smooth and ineffective for gripping the roadway.

Mud / Snow Tires (Knobbies) tend to pack mud and snow on the periphery of the tire rendering them useless for traction.

Flex-Trax "Self-Cleaning" solves for this issue as they continually throw the materials away from the surface of the tire

FLEX-TRAX™ eliminates this problem by using the opposite approach. Pascal chambers are used rather than bulky lug member extensions. Pascal is an fourteenth century physicist who had been the very first to use hydraulic pressure to achieve a mechanical advantage. .

Pascal stated "pressurized fluid solids in an enclosed holding chamber are equally dispersed in many directions". This results in a mechanical gripping action for FLEX-TRAX™. The enclosed holding chambers with load applied, allows fluid solids to be deposited, pressurized and then released outside the load region, with centrifugal force of rotation employed.

What is the Pascal chamber? Pascal-tech gripping holding chambers are actually, self-cleaning chambers, that along with the inverted step walls of the tread face, provide tremendous gripping forces when fluid solids are deposited inside the holding chambers and pressure from the load is applied. (the more load the more pressure, the more pressure on the chambers the more traction) then allow for quick discharge of fluid solids from the chambers as the pressure from the load is diminished and centrifugal force of rotation is involved.

The diamond shaped mini-chambers possess cavity wall structures consisting of inverted tapered step ledges to make its pattern. These kinds of mini-chambers combine to form larger chambers that likewise taper inward. The consistent placement of these kinds of profiles increases the gripping forces and quick release of fluid solids. The diamond patterns produce dual opposing chevron angles that support the opposing loads in all directions. This allows for maximum gripping in the forward and reverse directions.

Self-tracking is attained by way of the self-adjusting deflective angles. These kinds of angles adapt to the angle required to resist opposing forces. This feature is a key element in decreasing the primary tension needed during installation. The spring tension together with the rebound memory in the rubber, in conjunction with the opposing deflective angles, enables traction modules to spring to the center of the tire, providing for self-tracking of your installed FLEX-TRAX™.

FLEX-TRAX™ are easily cleaned and fold up for easy and compact storage in the included vinyl zipper bag.

FLEX-TRAX™ Offer An Advanced Self-Tensioning, Self-Adjusting and Self-Cleaning Snow Tire Chain System

FLEX-TRAX™ solve the matter involving tensioning tire chains through another approach. Self-tensioning is achieved as a result of the self-adjusting deflective angles. FLEX TRAX™ adopt the angle necessary to defy opposing pressures and allow the device to tighten itself upon the tires.

The engineered mechanics in our advanced traction model, as opposed to tire chains, coincides with the motion of the tire, taking full advantage of the applied forces throughout installation and operation. Everyone is so confident at FLEX-TRAX™, that we provide the only three-year manufacturer's warranty on any type of tire chains sold today. Try to find any warranty on other snow chains. Our merchandise is covered by a three-year limited manufacturer's warranty against material and workmanship defects and they work great.

Many customers ask;

"What is the difference between SnoClaws, GoClaws and WeatherClaws™?"

All Rights Reserved- Patent Development Company, LLC

FLEX-TRAX™ Advanced Traction Systems

D. Anthony Bright / CEO / Inventor / Founder

Exclusive rights See "TESTIMONIALS"

This material may not be published, broadcast, rewritten or redistributed WITHOUT WRITTEN AUTHORIZATION.

COPYRIGHT AND TRADEMARKS

Very Durable & Unique! Self-cleaning, Self-tensioning, Positive Locking traction device that actually gets tighter with loads applied.

Utility Patent

Method & Apparatus

FLEX TRAX™ Style And Design

Patent # 6308757

Patent for Method & Apparatus

Why does the obvious gaps between the trax cause no problems?

Answer- The Vehicle's Differential Slip, provides for the Flex-Trax Grip!

If your car did not have a differential, the wheels would have to be locked together, forced to spin at the same speed. This would make turning difficult and hard on your car: For the car to be able to turn, one tire would have to slip.

Unlike Tire Chains No Damage with Flex-Trax

We are Proud of our 15 YEARS IN BUSINESS

&

Zero damage to vehicles, tires, wheels and roadways!

New Danger for Drivers

Broken Chains on Roadways

It was reported, that in a single day 37 Vehicles suffered flat tires in one small Washington State Town due to these Broken Chains in the Roadway.

What is the Real Cost of Cheap Tire Chains? Destroyed Four Homes and approx 400,000 acres in Kansas and Oklahoma

Read more.....New Danger!

and More Serious Problems

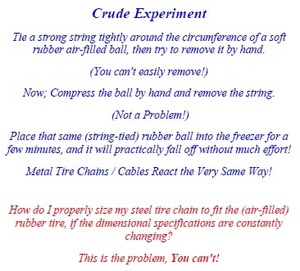

You should not expect a ridgidly affixed metal tire chain to remain mounted to your tire with temperature fluctuations and dynamic loads imposed.

Chains and cables are not resilient, will not flex with the applied loads, and cannot rebound to their original shape or mounting configuration once they are exposed to the inherent characteristics and dynamic loads of a tire.

Flex-Trax is designed with a Special Proprietary Polymer Rubber which resist elongation with excellent rebound memory. Said materials that are abrasion resistant, split / tear / cut resistant, cold stress cracking resistant, UV and Mold resistant. (We have hit the unit with a 20 Lb sledge hammer at -40F without even a dent.) Our materials are designed to provide excellent frictional adhesion when needed, without suffering premature failure from abrasive wear. (We have tested to over 800 miles on hot dry pavement with negligible wear.) * The traction pads become softer once exposed to dry pavement use resulting in a smoother ride, and become harder to bite into snow and snow-packed ice once exposed to these conditions. Clients that have properly cleaned and stored our product have reported an average service life of 6-8 years. This Inventor asked the question, "If metal is a good traction material for highway service, why then are tires not made of steel?"

* The traction pads become softer once exposed to dry pavement use resulting in a smoother ride, and become harder to bite into snow and snow-packed ice once exposed to these conditions.

Rubber has Better Friction Properties (coefficient of friction) than that of steel against all various surfaces!

Independent Dry / Wet Skid Test

GoClaws VS Studded and Radial Tires Advanced Traction System designed for use in mud, sand, slippery grass, snow, snow-packed ice, as well as occasional dry pavement use.

Ask yourself- If Metal is the preferred traction material, why then are tires not made of steel? Things that make you say Hmmmm.